Our Philosophy

The journey to success is never-ending. There is always something new to accomplish after each milestone.

In order to gain credibility in the market, we aim for growth and we adhere to a defined set of work ethics. As a result, these conventions help us deliver high class products to our clients and customers.

Honesty

Transparency

Commitment

Quality Assurance

about FERMALI SA

Vision

Dreams without action are just dreams. It is action with a vision that makes a difference. Through our undying faith and belief in our potential, determination, and dedication, we have kept our dreams alive.

With our constant drive to improve, we have now launched TMT bars that ensure strength and trust.

Among Fermali SA’s top priorities is brand positioning. A strong emphasis has been placed on quality and customer satisfaction to increase brand and product under Fermali SA.

about FERMALI SA

More than 6 years of experience

It is a formidable and the newest force to build a future perfect construction. A testament to the unmatched trust of Fermali SA, we are one of the best steel manufacturers using industry leading innovative automation. Every product has more load carrying capacity because of its supreme strength and ductility. Not to mention its enhanced earthquake resistant properties. Why wait? Lay an unshakable foundation of your dreams with Fermali SA!

Size

6mm, 8mm, 10mm, 12mm, 14mm, 16mm, 20mm, 32mm

Quality

Grades: Fe 400,Fe 450 Fe 500, Fe 550

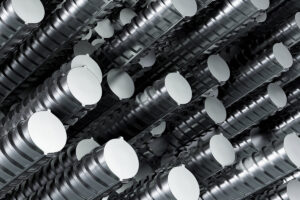

Infrastructure’s Backbone

We Deliver Strength and Stability

It wouldn’t be a boast to claim that TMT bars are the backbone of our daily lives. From the homes we live to the offices we spend our days working, most modern structures get their strength from TMT steel bars interwoven through them.

The modern construction industry would undoubtedly fail to survive without TMT bars.

Superior Savings

Unmatched Quality

Unprecedented Technology

With the constant support of experienced professionals, we are offering optimum quality Thermo Mechanically Treated TMT Bars.

Driven by Innovation

Building a strong Future with Technology

Thermo Mechanically Treated Bars or TMT Bars are manufactured by using a unique technique that leaves them with a tough outer area and a soft inner core. This makes the TMT bar strong but also flexible.

We use the advanced German “CRS” technology to manufacture the TMT bars. This technology exposes the steel to temperatures as high as 1100 degree Celsius. The steel ‘billets’ are then passed through rolling mills to give them the desired shape.

After this, the bars are quickly cooled with a process called quenching through high-pressure water spray. This cooling process makes the outer area of the bars extremely strong while providing the inner core with ductility.

Super Quality

We bring new advantages.

We bring the highest grade products with latest technology

More strength and ductility

Corrosion-resistant

Fire-resistant

Earthquake proof

Cost-effective

More Strength = More Savings

More load carrying capacity of the TMT Bars. For a given design load, fewer number of TMT Bars or reduced diameter is required.

- Easily carries design load without any structural cracks.

- Optimized design leads to reduced consumption.

- Savings on the quantity.

More Eco-friendly

Strongest and most eco-friendly TMT Bars

- Our sustainable manufacturing practices have reduced the environmental impact of our products.

- Our policies and guidelines enable you to make an informed and sustainable choice.

More Assurance

Ensures peace-of-mind while Purchasing

- Fermali SA are available in pieces of consistent dimensions.

- Each piece is of accurate length, diameter and weight.

Construct a Stable Future

Giving your Construction a New Strength

The most important aspect of Fermali SA TMT bars is the quality of our products and the satisfaction of our customers.

We have multiple Grades of TMT bars for a stronger construction with the latest technology that yields “Better Value for Money”.

Making every structure stronger!

We bring the bars. You build on them.

Our TMT bars have now become the gold standard in construction and are used widely in diverse projects:

- Residential projects

- High Rise residential buildings

- Office / industrial structures

- Dams

- Long span bridges and flyovers

- Large structures such as Malls, Schools, Airports, Hospitals, etc.

- Underground structures

- Underwater or marine structures.

global relationships

Certifications

Strength lies in the trust and faith we bring with our bars.

- Higher Ductility

- Better Weldability

- Increased Elongation

- Lower Carbon Level